Packaging Audit: A Practical Guide

A packaging audit is a detailed review of your packaging materials, processes, and costs. It helps supply chain leaders uncover hidden inefficiencies that affect margins and operational performance. A well-executed audit strengthens decision-making and supports long-term cost savings and efficiency improvements.

The Strategic Importance of a Packaging Audit

Packaging audits give supply chain leaders clarity on areas where costs rise without notice. Many teams try to reduce spend but lack visibility into small inefficiencies that add up over time. These gaps often impact savings, efficiency, and compliance. A thoughtful audit reveals where materials, workflows, or purchasing habits fall short. It validates your efforts and provides a path to smarter decisions. It also supports compliance with evolving regulations, which reduces the stress of potential risks.

Core Steps in Conducting a Packaging Audit

A comprehensive packaging audit follows a clear structure. Begin by defining the scope and goals of the audit. Set objectives that address your main objectives, such as cost reductions, material optimization, or compliance concerns. Clear goals will guide the data you need.

Next, collect data on current materials, specifications, supplier details, and usage patterns. If you lack specialized tools to gather data, start with simple measurements. Record dimensions, weights, and unit costs manually. Investing in advanced tools and systems will simplify this process and eliminate the errors that come with manual tracking, but if you don’t have the resources now, you still have options for tracking your data.

Analyze material use to find excess usage, outdated specs, or overspending. Look for ways to consolidate materials or streamline workflows. A strong analysis identifies real cost-saving opportunities.

During the process, supply chain disruptions may shift timelines. Build flexibility into data collection by documenting details in stages. Maintain consistent communication with internal teams. Gather information in small batches when full reviews are delayed. This ensures you keep the audit moving forward.

Evaluating Current Packaging Materials

To evaluate your current packaging materials, begin with a full inventory of the packaging materials you use across all product lines. Check each material for quality standards and performance in transit. Look for extra layers that add cost without providing needed protection. Lastly, confirm whether existing materials meet both current needs and long-term goals.

Analyzing Packaging Design and Efficiency

Next, review your packaging design for structural soundness and brand alignment. This may feel daunting if you lack design insight or advanced testing tools, but there are simple ways to measure this. Use simple metrics to assess packaging effectiveness. Track breakage rates, dimensional accuracy, and customer returns, complaints, and reviews. Check how well products fit in their primary and secondary packaging. Identify gaps that cause damage or add unnecessary expense.

Addressing Compliance and Regulatory Standards

A packaging audit ensures your materials and practices meet evolving regulations. This reduces the risk of fines, delays, or legal actions. As a business leader, it’s understandable to be worried about changing rules in different markets. An audit will help provide a clear view of where updates are required and avert compliance lapses.

Sustainable Packaging Insights

A packaging audit also reveals new ways to reach sustainability goals. It identifies materials that reduce waste and improve environmental performance. You may discover lightweight options, recycled content, or simplified designs. It’s important to be aware of the pressure to meet sustainability goals while managing strict budgets. An audit helps balance both by finding solutions that support cost savings and environmental responsibility.

For more sustainable packaging info, check out these five steps to improve the sustainability of your packaging.

Identifying Real-World Success Stories

Companies across industries have seen big wins by improving their packaging processes. Some cut material costs by removing unnecessary layers. Others boosted sustainability by switching to recycled or lightweight materials. Many reduced product damage and shipping costs with smarter designs. And in some cases, brands listened to frustrated customers and redesigned packaging to make products easier and more enjoyable to use. The following examples show how thoughtful packaging changes can strengthen a brand and create lasting success.

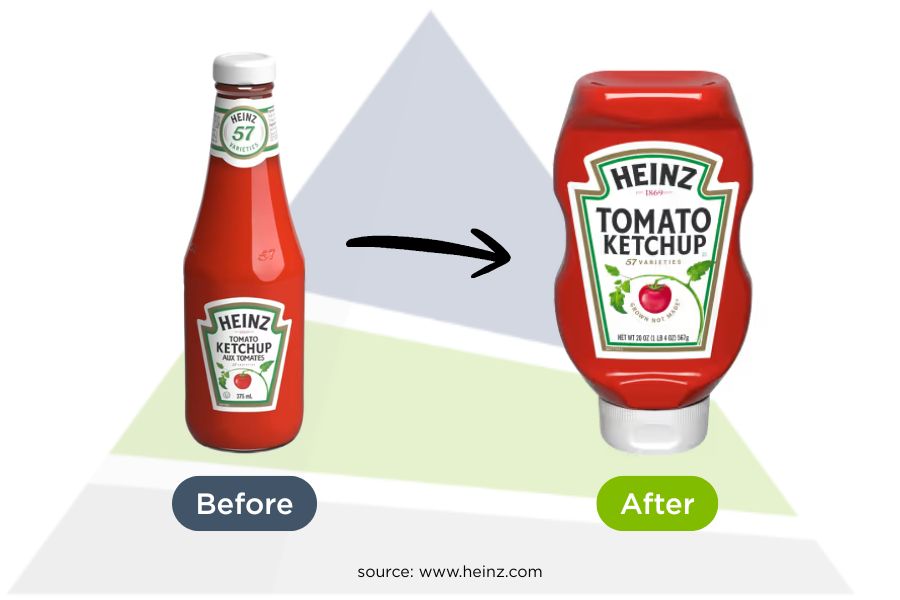

How Heinz Turned a Frustration into a Win

For decades, Heinz’s glass ketchup bottle was an icon. But anyone who has ever tried to get ketchup out of it knows the struggle — one minute you’re tapping the 57, next you’ve got a mess of ketchup on your plate. Customers loved the brand but hated the hassle, and Heinz realized this pain point could threaten its market leadership.

The Game-Changing Redesign

In 2002, Heinz introduced an upside-down squeezable plastic bottle with a clean stay cap. This simple yet smart change solved the problem. The ergonomic design and valve system made ketchup flow easily without a mess, turning frustration into convenience.

The Impact

Consumers loved it. The new bottle earned the highest approval rating in Heinz’s history and quickly became the standard. Today, most Heinz ketchup is sold in this format, and the brand remains the top choice in the U.S., with nearly 198 million Americans using it in 2020. In another major move, KraftHeinz also announced that it will reduce the use of virgin plastics by 20% globally by 2030.

Key Takeaways for Brands

- Listen to Your Customers: Real-world frustrations are opportunities for innovation.

- Update the Classics: Even beloved products can benefit from a fresh approach.

- Adapt to Stay Ahead: Consumer needs evolve, your packaging should too.

- Sustainability is a Must: Packaging laws and regulations are here, make sure your goals are aligned.

How Justin’s Won with Convenience

Justin’s peanut butter started out in traditional jars, but that wasn’t enough to stand out in a crowded market. The jars were bulky and inconvenient for busy, health-conscious consumers who wanted snacks on the go. Justin’s needed a way to differentiate and meet the needs of its target audience.

The Smart Redesign

The solution? Single-serve squeeze packs. These portable packs made it easy to enjoy peanut butter anywhere without utensils. Compact and portion-controlled, they fit perfectly into active lifestyles and solved the problem of inconvenience for people on the go.

The Impact

The squeeze packs transformed Justin’s market presence when it was introduced in 2006. They attracted new customers, opened doors to national retail chains, and drove significant growth. By 2016, this innovation helped Justin’s achieve a $281 million acquisition by Hormel Foods.

Key Takeaways for Brands

- Prioritize Convenience: Packaging that fits modern lifestyles can dramatically boost appeal.

- Innovate with Purpose: Address specific consumer needs to stand out in competitive markets.

- Leverage Packaging for Growth: Smart design can unlock new distribution channels and fuel expansion.

Heinz and Justin’s prove that packaging audits are a gateway to innovation. By listening to consumer pain points and adapting to changing lifestyles, both brands turned simple packaging changes into powerful growth strategies. Heinz solved a decades-old frustration with a user-friendly redesign, while Justin’s created a portable solution that opened new markets. These stories show that when packaging evolves to meet real-world needs, it can transform brand perception, drive sales, and secure long-term success.

Putting Packaging Audit Findings into Action

Once your packaging audit is complete, communicate the findings clearly across departments. Share both quick wins and long-term opportunities. Use visuals or summaries to illustrate how changes impact cost, efficiency, and compliance. Transparent communication builds trust with stakeholders and helps teams act on the data. This helps bridge the gap between audit insights and daily packaging operations.

Maintaining Ongoing Packaging Audits

Consistent packaging audits protect your brand and reduce costly mistakes. They keep your team aligned with regulations, quality standards, and customer expectations. The following steps ensure your packaging strategy evolves as your business grows and market demands change. Ongoing audits build trust, improve efficiency, and help you stay competitive in an ever-evolving market.

Action Plan for Maintaining Packaging Audits

- Create a Packaging Quality Control Checklist to review materials, labeling, and compliance before production begins.

- Schedule Regular Packaging Quality Inspections during manufacturing to catch errors early and prevent costly rework.

- Perform Packaging Testing for durability, safety, and performance under real-world conditions to ensure reliability.

- Document Every Audit and share findings with your team to maintain accountability and track improvements over time.

- Update Packaging Processes based on audit results to align with evolving regulations, sustainability goals, and customer expectations.

- Train Your Team on audit procedures and quality standards to keep everyone aligned and proactive.

How Paramount Global Can Help Optimize Your Packaging Processes

Paramount Global brings decades of experience in conducting comprehensive packaging audits. Our team identifies cost-saving opportunities, advises on regulatory compliance, and builds sustainable packaging solutions that support your goals. We work across many industries and understand the challenges that supply chain leaders face. By partnering with our experts, you gain immediate access to practical insights and actionable recommendations that strengthen your entire packaging operation.

From global product sourcing to custom packaging and supply chain solutions, we’ve got you covered for all your packaging and logistics needs.

Ready to take the next step? Contact us today to schedule a free packaging consultation.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.