LTL vs. FTL: About Truckload Shipping

When it comes to freight transportation, the two most common shipping methods are Less Than Truckload (LTL) and Full Truckload (FTL). As the names suggest, each method serves a specific purpose based on the volume being shipped. Understanding the distinctions and advantages of LTL and FTL shipping enables businesses to make informed decisions based on their specific shipping needs. In this article, we will highlight the benefits and drawbacks of each shipping method so you can choose the best option for your business’s unique needs.

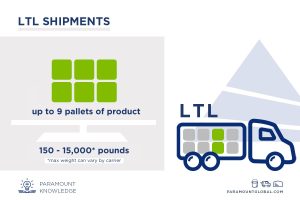

What is less-than-truckload (LTL) shipping?

Less-than-truckload shipping (LTL) is an efficient option for moving smaller loads of freight without having to wait until you can fill a full truck. LTL freight shipping only takes up a portion of the available space in a truck for its shipment. It is ideal for small shipments and is cost-effective because it combines shipments from multiple customers onto a single truck. By consolidating small loads with other shipments, LTL allows for cost-sharing among multiple shippers.

LTL is an ideal shipping mode for the following types of freight:

- less than 9 pallets

- takes up less than 12 linear feet of trailer space

- load weight is 150-15,000 pounds

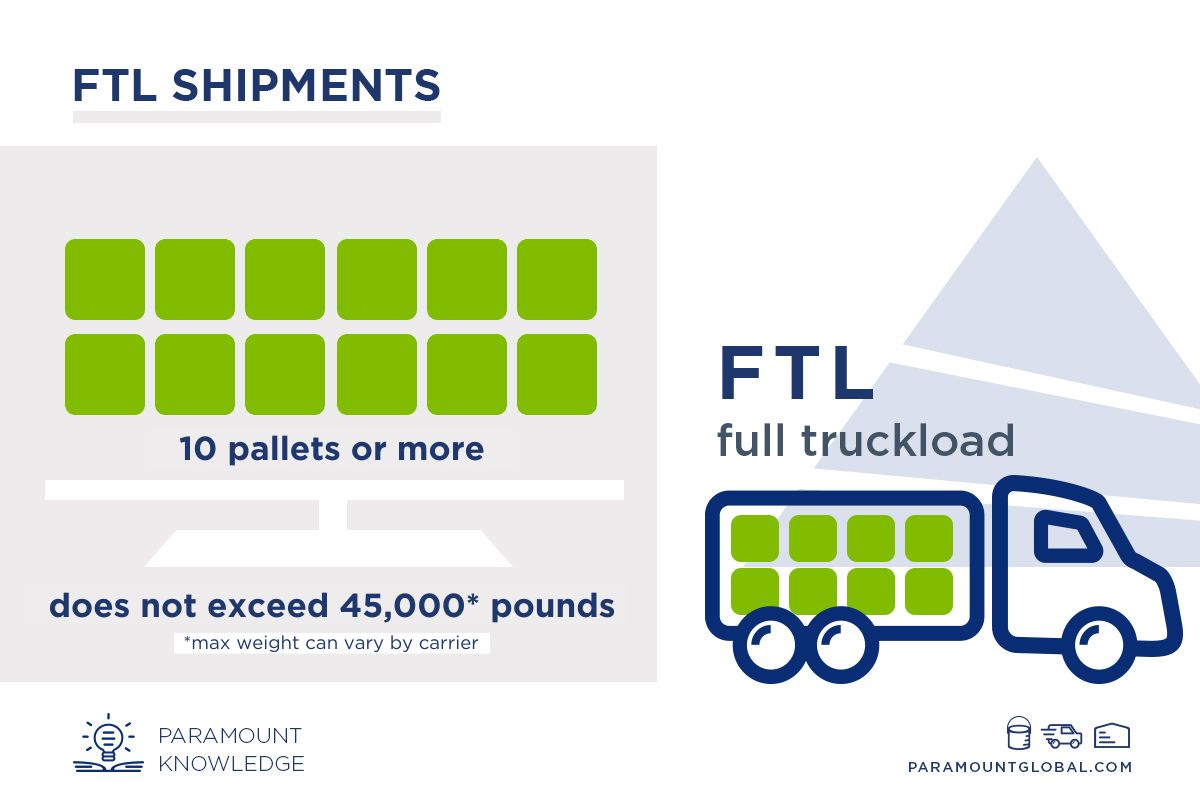

What is full truckload (FTL) shipping?

Full Truckload Shipping, otherwise known as FTL shipping, is ideal for transporting larger shipments to a single customer. It uses a dedicated cargo truck that can accommodate 26 non-stackable pallets to 52 stackable pallets and can handle a load weight of up to 45,000 pounds. By having a single target destination, FTL shipments save time with a direct route, minimizing the risk of product damage from multiple stops and shifting of goods.

FTL is an ideal shipping mode for the following types of freight:

- 10 pallets or more

- takes up between 48-53 linear feet of trailer space

- load weight not exceeding 45,000 pounds

What is the difference between LTL and FTL?

The main differences between LTL and FTL shipping are in terms of load size, cost savings, delivery times, handling and risk, flexibility, and space requirements. Let’s take a closer look at some of the key differences between shipping methods.

Load Size

LTL shipments are smaller and occupy only a portion of a truck’s space, while FTL shipments fill an entire truck.

Cost Efficiency

LTL is generally more cost-effective for smaller shipments, while FTL is more suitable for larger and heavier shipments.

Transit Time

FTL shipments typically have shorter transit times due to fewer stops and a dedicated truck, while LTL shipments may take longer due to multiple intermediate stops and the consolidation of goods along the way.

Handling and Risk

FTL shipments have a lower risk of product damage since they are not shifted around through multiple stops, while LTL shipments may be subject to more handling and have a higher risk of damage.

Flexibility

LTL offers more flexibility in terms of shipping smaller quantities and consolidating goods from different suppliers, while FTL is ideal for large shipments heading to a single destination.

Space Requirements

FTL requires a dedicated truck, while LTL shipments can be accommodated in a shared truck with other customers’ goods.

When to Use LTL and FTL Shipping

When it comes to logistics, the choice between LTL and FTL freight shipping can have a significant impact on the efficiency and cost-effectiveness of your business. Let’s take a look at the most significant differences between types of shipments and some factors to consider during your decision-making process.

When to Use LTL Shipping

LTL freight shipments should be used if the size of your shipment will only fill a partial truckload. The number of pallets should be less than 10, and the weight of your shipment should not exceed 15,000 pounds.

Typically, LTL shipping costs are lower than FTL because you only pay for the space you use. However, it often involves additional risks and fees. When shipping LTL freight, increased cargo handling at distribution centers and terminals along the way can lead to potential damage or loss during unloading and reloading. Long delays can also arise unexpectedly, affecting delivery timelines. LTL freight rates may also include extra charges associated with freight classification and accessorials.

LTL is the best choice for small to medium-sized businesses that do not ship large quantities of goods and can benefit from the lower cost of splitting a truckload.

Keep the following guidelines in mind to help decide if an LTL carrier is right for you:

- When you have a small shipment that doesn’t fill an entire truck

- When you have a shipment that needs to be delivered to multiple locations

- When you’re looking for a cost-effective shipping option

- When you need more flexibility in terms of shipping dates and times

What about STL Shipping?

If you have higher volume LTL shipments, there is another option called shared truckload or STL. Similar to LTL shipping, STL shipping combines freight from multiple businesses to optimize trailer space. By sharing trailer space, each shipper pays only for the portion they utilize, resulting in significant cost savings. In addition to cost savings, shared truckload shipping contributes to your company’s sustainability efforts. Consolidated shipments mean fewer trucks on the road with underutilized space, leading to reduced fuel consumption and lower carbon emissions compared to full truckload shipping. While the terms LTL and STL may seem interchangeable due to their similarities, there are some important differences to note:

- LTL shipments face size limitations up to 9 pallets, while STL can accommodate up to 20 pallets, with shippers paying only for the space they need.

- LTL cargo has a specific freight class affecting pricing and weight allowances, while STL handles various freight types eliminating confusing freight classes.

- STL weight restrictions are less stringent than LTL, providing more flexibility for heavier shipments.

- LTL freight may incur additional accessorial fees such as re-weigh, re-class, or residential fees, while STL offers the best rates without unexpected expenses.

- LTL shipping can get shipments out faster than FTL, but terminal stops can cause delays, damage, and loss. STL freight travels on a terminal-free route directly to its destination, ensuring it arrives intact and on time.

- Tracking LTL shipments can be complicated due to distribution center stops and multiple trucks, whereas STL shipments stay on a single truck for the entire trip, making it easier to monitor their location at any given time.

- STL contributes to environmental benefits by consolidating shipments and skipping energy-intensive terminals, reducing the number of trucks on the road and making it a more environmentally friendly option for smaller loads.

- STL shipping is less commonly available than LTL or FTL solutions. Make sure to check with your provider if STL shipping is an available option.

When to Use FTL Shipping

FTL freight shipping is the best shipping method for businesses that need to transport a large volume of goods. FTL should be used if your shipment size will fill the entire space in a truck. The number of pallets should be more than 10, and the weight of your shipment can be up to 44,000 pounds, though generally, FTL shipments weigh between 10,000-20,000 pounds.

There are higher costs associated with truckload freight, however, if you are shipping large loads or heavy loads, the direct service to your final destination will outweigh the lower price of LTL shipping. You’ll also avoid any potential mishaps because FTL shipping has much less risk since your single shipment will pass through fewer hands throughout the entire journey, reducing the opportunities for damage and loss that can be the case with LTL shipping.

FTL shipping offers several benefits over LTL shipping, including:

- Faster transit times: FTL shipments typically have shorter transit times than LTL shipments because they do not have to be consolidated with other shipments.

- Reduced risk of damage: FTL shipments are less likely to be damaged than LTL shipments because they are not handled as often.

- More control over the shipping process: FTL shippers have more control over the shipping process than LTL shippers, including the ability to choose the carrier, the route, and the delivery time.

Which type of shipping is best for your business?

Ultimately, the choice between LTL and FTL shipping depends on your business’s specific needs and requirements. Various factors such as shipment size, cost, transit time, flexibility, and handling risks should be considered. By understanding the key differences between these shipping methods, you can make an informed decision that aligns with your business goals.

Handle Your Shipments More Efficiently and Cost-Effectively Today

Time and cost will likely be a determining factor in which option will work best for your business. At Paramount Global, we offer unparalleled expertise in managing the complexities of packaging and supply chain logistics, ensuring optimal efficiency, cost-effectiveness, and compliance. Our team of seasoned professionals have in-depth industry knowledge and a global network of partners to provide tailored solutions that meet the unique requirements of each customer. Whether you need efficient shipping, customs clearance, or specialized packaging, Paramount Global is your trusted partner for seamless and reliable logistics management. Contact us today to experience the difference our expertise can make for your business.

This article was originally published on July 22, 2019 and was updated on May 1, 2024.

Hayley is a marketing professional and copywriter with a background in crafting content for a diverse range of industries. She has been writing about packaging and supply chain logistics for Paramount Global since 2022. She specializes in explaining complex topics in a clear and engaging way and is an advocate for sustainability in packaging and supply chain management.

Read More

For over forty years, Paramount has been delivering perfectly integrated packaging and supply chain solutions.